![]() Homepage / Products / Easylube® Automatic Lubricators / Nexus Series

Homepage / Products / Easylube® Automatic Lubricators / Nexus Series

A smart automatic lubrication management system integrating science, technology, engineering and mathematics

Catalog Download

Catalog Download

Specifications and Installation Instructions

Specifications and Installation Instructions

Quality Assurance Certification

Quality Assurance Certification

This product has received multiple patents from various countries!

This product has received multiple patents from various countries!

|

Easylube® Nexus Automatic Lubricator

|

|---|

|

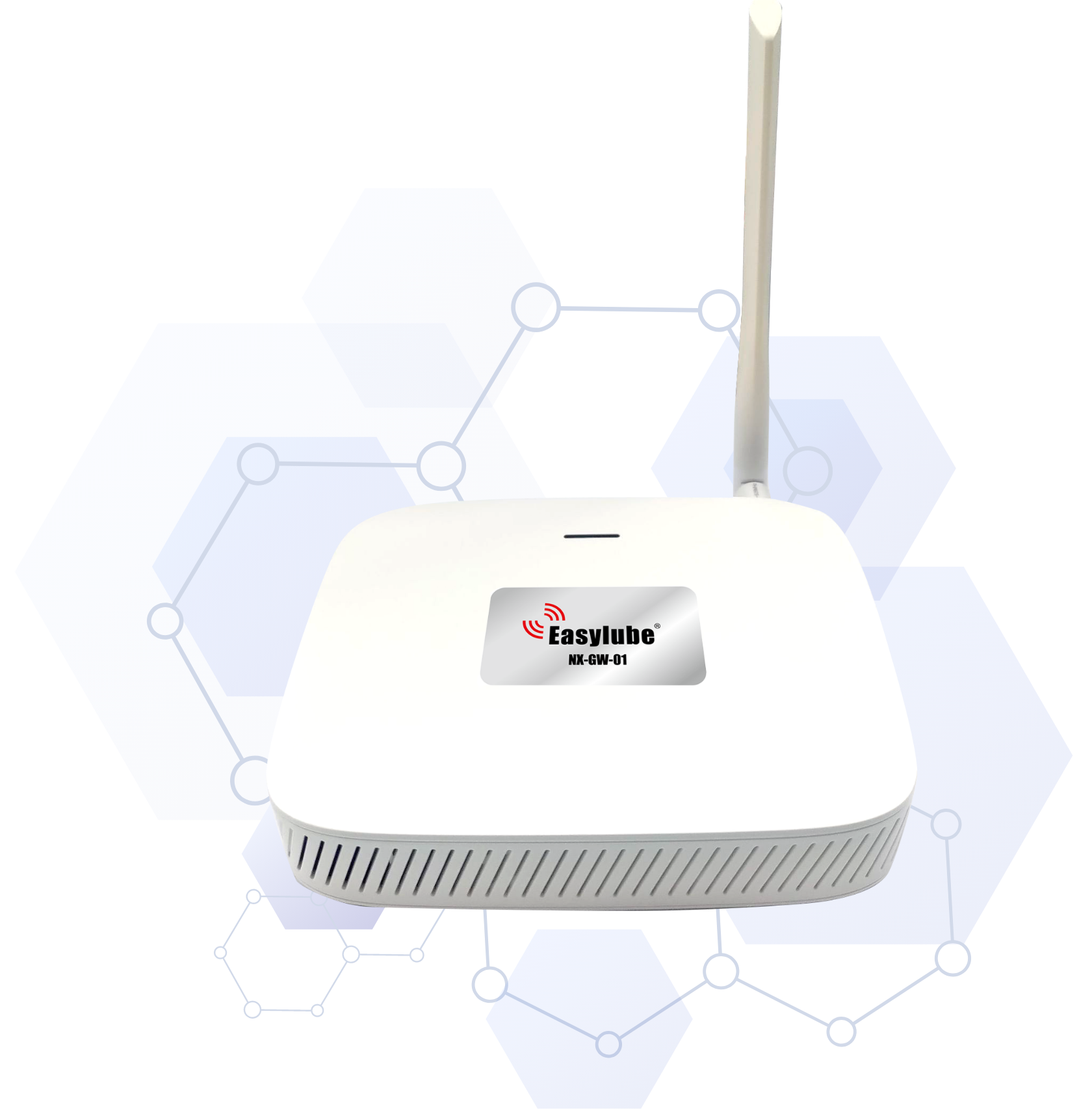

Easylube® Nexus Gateway

|

|---|

|

Easylube® Nexus LINK

|

|---|

|

Easylube® Nexus Surface Temperature Sensor

|

|---|

|

Easylube® Nexus FAQ

|

|---|

|

|

Current Grease Volume |

|---|

|

|

Current Battery Power |

|---|

|

|

Pipeline Pressure |

|---|

|

|

Current Temperature |

|---|

|

|

Signal Strength |

|---|

|

|

Real-time Information |

|---|

|

|

Period Setting |

|---|

|

|

Standby |

|---|

|

|

Restart |

|---|

|

|

Quick Reverse |

|---|

|

|

Forced Greasing |

|---|

|

|

Reconnect |

|---|

Scan the QR code to download Easylube® LINK

The NFC sensor is located at the indicator light to implement on-site patrol, record the inspection report and issue control instructions.

Compliant with IECEx International Certificate

Smart battery check and protection

Non-sparking safety motor

Intuitive tri-color indicator lights

Guaranteed Lifespan of 5+ Years

Safety structure without setting buttons and protruding light indicators. It also adopts a special safety and explosion-proof housing, which can completely withstand various harsh environments!

| High and low temperature resistance | |

| Dustproof |

| Waterproof | |

| Anti-collision |

Easylube® Nexus Pak is a replica of the dual layer grease cup and bag design created in 1992. When replacing consumables, only the grease bag (inner bag) needs to be replaced. It will not leak due to frequent disassembly and damage to the sealing effect.

| The outer cup is made of high-strength temperature-resistant, impact-resistant material, which can withstand harsh external environment for a long time | |

| The inner cup is designed for economy, convenience, and easy replacement, reducing the cost of consumables and saving long-term maintenance cost! |

|

RFID technology (NFC) cooperates with the inspection software to implement "on-site inspection" service management. |

|---|

|

With IP66 dustproof and waterproof rating, it can overcome severe pollution application environment. |

|---|

|

24-hour active monitoring, once the equipment is abnormal , it will immediately blink the warning light and notification will be displayed on your LINK APP via the Easylube® Nexus Gateway. |

|---|

|

The patented grease feedback pressure monitoring system can ensure that grease is added systematically into the bearing for lubrication. |

|---|

|

The re-greasing interval can be set according to the bearing operating conditions to the range of 0.5-12 months |

|---|

|

The lubricator self-test function can be used to confirm whether the driving system is operating normally or not. |

|---|

Wireless Transmission Works with :

LAN

Wi-Fi

Mobile Network

Accessories:

LoRa antenna *1

Power supply *1

Mounting bracket *1

|

Multiple international certifications & quality assurance. |

|---|

|

Anti-interference/ High Penetration/ High Sensitivity. |

|---|

Within a range of 2 kilometers

One Easylube Gateway can cover 1000 automatic grease lubricators

Depending on environment obstacles and the interconnection frequency influences

|

AI electrical control system will automatically detect battery level to repeatedly fully utilize the battery and save cost. |

|---|

|

Supports collaboration and sharing information. |

|---|

|

Ensures the inspectors are in place for inspection. |

|---|

|

Visual chart records are critical. |

|---|

The sensing point is located on the metal base, and it will measure the surface temperature. The data is connected to the wireless Easylube® Nexus Gateway, users can check the temperature sensing report anywhere and anytime.

Reinforced Protective Shell

Wide Temperature Detection Range

Intuitive Indicator Light Design

Support remote installation

|

Record, returns temperature measurement data. |

|---|

|

With IP66 dustproof and waterproof rating, it can overcome severe pollution application environment. |

|---|

Detect the equipment's temperature send the data to the APP

Detect -30 ~ 180℃