![]() Homepage / Partnership

/ Equipment Manufacturer Cooperation

Homepage / Partnership

/ Equipment Manufacturer Cooperation

Lubrication management means that the enterprise adopts scientific management methods, reasonable selection, and use of modern automatic lubricators, to achieve correct and simple management methods, to keep the machinery in a good lubrication state.

Professionalism

Intelligence

Simplicity

Safety

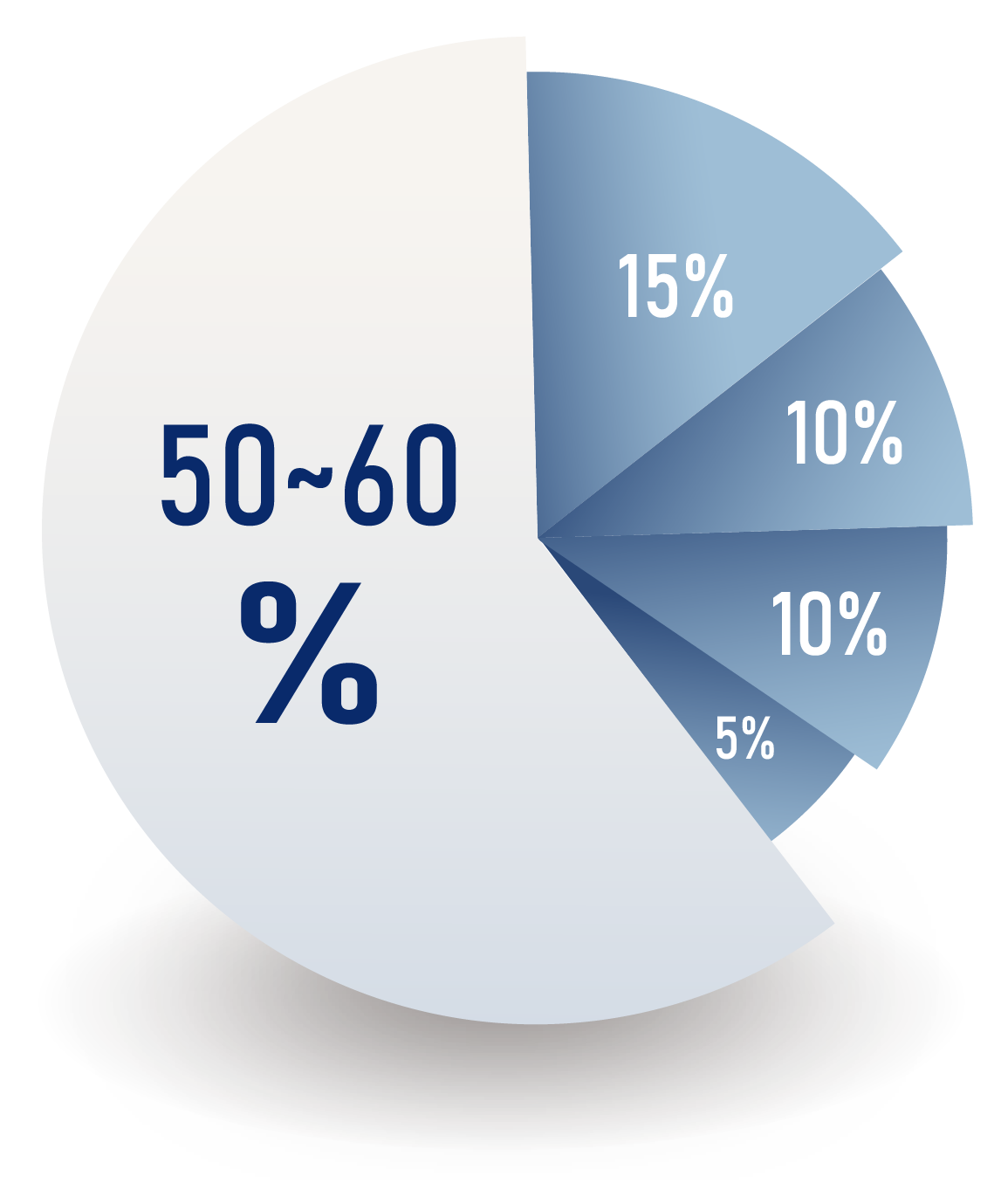

50~60%:Incompetent lubrication maintenance

15%:Solid / Liquid contamination

10%:Improper bearing installation

10%:Damaged by other reasons

5%:Improper lubricant

50% ~ 60% of bearing failures are caused by lubrication problems. If the equipment does not fail due to overload, or a design or manufacturing defect, then its failure can usually be traced back to a lubrication problem.

Therefore, lubrication management and maintenance are very important for machinery and equipment to avoid serious consequences of lubrication failure.

Easylube® can assist equipment manufacturers to construct automatic management and maintenance plans by utilizing scientific and reasonable lubrication means according to the operating conditions of the machinery. Every user then can follow the lubrication guidelines provided by the "Original Equipment Manufacturer" easily, hence complying with the consumables (grease cup and lithium battery) replacement suggestion provided in the "Mechanical Manual". This will not only prolong the service life of the equipment, improve the operation rate of the equipment, create the maximum production efficiency of the equipment, but also increase the output value and save more time and cost for your customers.

The use of scientific lubrication management can greatly reduce equipment damage and lubrication maintenance costs.

Prolong the service life of the equipment and reduce the cost of maintenance personnel or maintenance due to downtime.

Reduce operating resistance, reduce energy consumption, and save electricity or fuel costs.

Reduce the time and frequency of production downtime due to wear and tear of parts, and greatly improve production efficiency.